Beyond Activated Carbon: Why PFAS Treatment Solutions Need a New Generation of Technology

November 2025

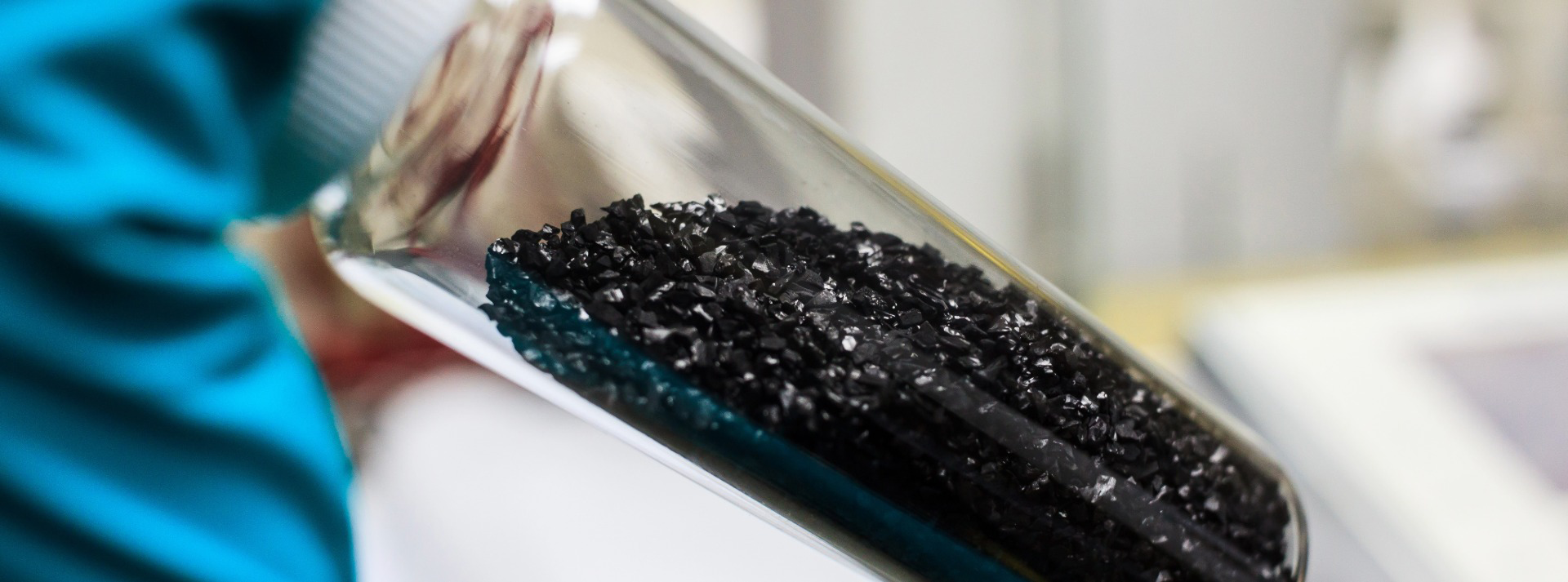

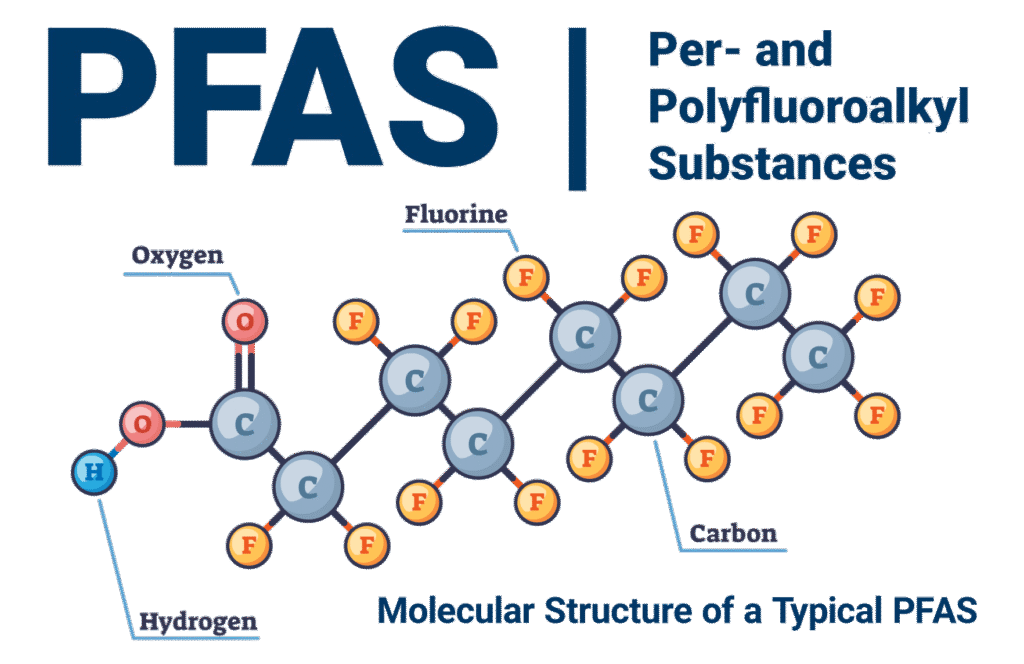

Per- and polyfluoroalkyl substances (PFAS) are some of the most persistent and complex contaminants ever encountered in Australia’s waste and water sectors. For decades, facilities have relied heavily on activated carbon to manage PFAS present in landfill leachate, wastewater, and industrial runoff, but the environmental landscape has changed.

PFAS concentrations are rising. Regulations have tightened. Community expectations have shifted. And the scale of the issue now exceeds what first-generation solutions can reliably or sustainably manage.

It is becoming increasingly clear that Australia needs a new generation of PFAS treatment solutions that are not only effective, but also environmentally responsible, economically viable, and adaptable to a rapidly changing regulatory framework.

This article explores why activated carbon is no longer enough on its own, the challenges it presents, and how modern extraction technologies are redefining what PFAS remediation can look like.

Quick Links

The Limitations of Activated Carbon in PFAS Treatment Solutions

Activated carbon has been widely used as a PFAS “solution,” largely because it was familiar, readily available, and relatively simple to integrate into existing infrastructure. However, its challenges have become more difficult for operators to overlook.

1. It creates its own waste stream

Once carbon becomes saturated, it must be replaced, transported, and either incinerated or regenerated – both carbon-intensive, costly processes that shift the problem downstream rather than eliminate it.

2. Short-chain PFAS breakthrough is common

Activated carbon can perform reasonably well on long-chain PFAS like PFOS. In addition, short-chain compounds, which are increasingly common in Australia, slip through far more easily, leading to frequent breakthrough and inconsistent compliance.

3. High and unpredictable operational costs

The quantity of carbon required is dependent on local PFAS concentrations, water chemistry, and flow variability. For many landfills and wastewater plants, this results in unpredictable operational budgets and periodic system outages.

4. It captures PFAS - it doesn’t extract it

Carbon removes PFAS from water, but it does not destroy or isolate the chemical. The PFAS remains embedded in the spent carbon, creating long-term liabilities for waste processors, councils, and downstream treatment facilities.

5. Carbon was never designed as a long-term PFAS treatment solution

As PFAS becomes one of the most closely monitored contaminants in Australia, reliance on a legacy technology with inherent limitations is becoming increasingly difficult to justify.

Why Australia Needs Modern PFAS Treatment Solutions

As the waste, water, and environmental sectors face mounting pressure to meet NEMP 3.0, EPA discharge thresholds, and community expectations, three priorities have emerged:

- Remove PFAS — not just capture it: Modern PFAS solutions need to physically separate PFAS from water or solids in a form that is easier to isolate, monitor, and dispose of safely.

- Reduce secondary waste: A high-performing PFAS treatment method must minimise, or eliminate additional waste streams, so the environmental footprint does not simply shift elsewhere.

- Deliver scalable and cost-effective performance: Facilities need reliable systems that can treat thousands of litres per hour without exponential cost increases or complicated maintenance demands.

This next generation of PFAS treatment solutions is centred around extraction, not absorption, shifting from temporary solutions to long-term environmental outcomes.

The Rise of PFAS Extraction: The Next Generation of PFAS Treatment Solutions

Extraction technologies such as foam fractionation, gas fractionation, and multi-stage separation are gaining traction across Australia because they address the shortcomings of activated carbon directly. Key benefits include:

✔ Extremely low waste volumes

Instead of disposing of tonnes of spent carbon, extraction concentrates PFAS into a tiny, manageable volume.

✔ Proven effectiveness across long- and short-chain PFAS

Gas fractionation and foam-based processes target the surface-active nature of PFAS molecules, allowing them to separate effectively regardless of chain length.

✔ High throughput

Modern extraction systems can treat up to 20,000 litres per hour or more — ideal for landfills, wastewater treatment facilities and councils dealing with high-flow PFAS contamination.

✔ Lower long-term cost

By removing consumable media (like carbon) and reducing disposal requirements, extraction offers a more predictable and scalable operational cost profile.

✔ Environment-first remediation

Extraction aligns with global environmental principles — treat, isolate, minimise waste, and reduce downstream burden.

Why This Matters for Australia’s Waste and Water Sector

As PFAS regulation evolves, the industry must transition to solutions that:

- enable transparent data reporting

- meet EPA thresholds with consistency

- reduce long-term liabilities

- demonstrate environmental leadership

- support councils and operators in protecting communities

Large international waste companies often have multimodal PFAS solutions, but many rely heavily on older technologies. Australia now has an opportunity to lead with more agile, research-driven, localised solutions that reflect our unique regulatory framework and environmental conditions.

The shift “beyond activated carbon” is not simply a technological evolution, it is a cultural one. It signals that Australia is ready to adopt solutions that do more than manage PFAS; they actively work to remove it from our environment.

The Path Forward: Building PFAS-Free Communities Through Better Treatment Solutions

The transition to new PFAS treatment methods will require collaboration between:

- councils

- landfill and wastewater operators

- environmental consultants

- regulators

- research institutions

- technology providers

As PFAS phase-outs accelerate around the world, Australia has a critical opportunity to become a leader in next-generation, sustainable PFAS treatment solutions.

The challenge is significant, but so is the opportunity to lead.

By investing in extraction technologies backed by real-world trials, universities, EPA-licensed facilities and measurable outcomes, the sector can move confidently towards solutions that protect communities, ecosystems and future generations.

PFAS is not a short-term issue. It is solvable and the next generation of PFAS treatment solutions is already here.