Filtration Systems

Cooling/Heating Systems

Silencers

Diverter Damper

Exhaust Stacks

Providing sustainable solutions for the energy sector.

Ensuring projects are on time and on budget.

From consultation, design, construction to completion.

Solutions based engineering to address today's energy needs.

An ASX-listed company.

Engineering at its Best

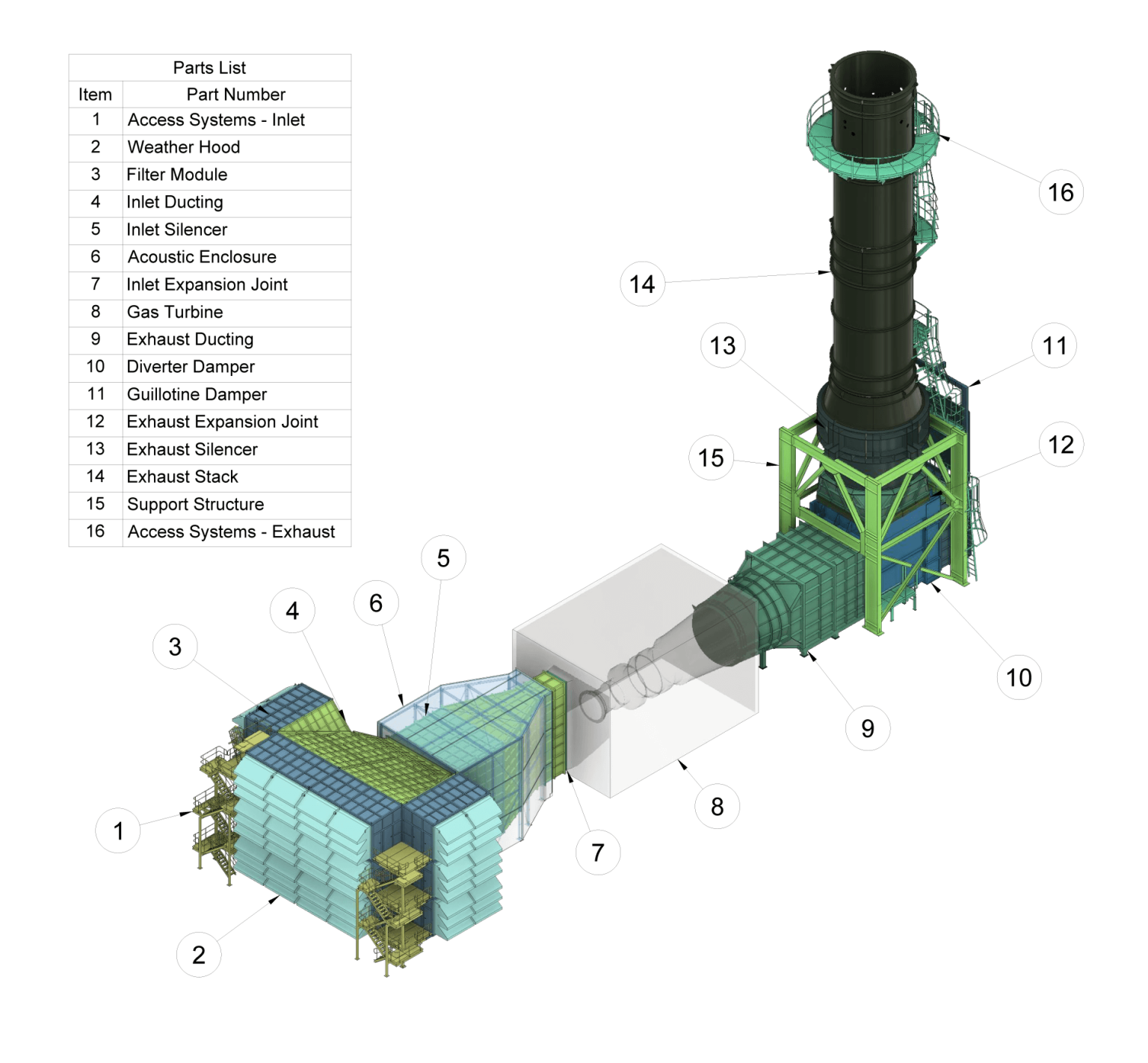

The Environmental Group provides a broad range of engineered products to the industry, such as gas turbine inlet filtration systems (filter houses), inlet cooling/fogging systems, acoustical components, expansion joints and complete exhaust systems with guillotine and diverter dampers. These products are applicable to new systems, upgrades, and retrofits, and spare part supplies.

While these complete systems are most commonly requested by our clients, we provide a range of other products to cover non-standard applications or specific requests. Our engineering services enable us tailor any of our products to meet clients’ requirements.

Engineering at its Best

The Environmental Group provides a broad range of engineered products to the industry, such as gas turbine inlet filtration systems (filter houses), inlet cooling/fogging systems, acoustical components, expansion joints and complete exhaust systems with guillotine and diverter dampers. These products are applicable to new systems, upgrades, and retrofits, and spare part supplies.

While these complete systems are most commonly requested by our clients, we provide a range of other products to cover non-standard applications or specific requests. Our engineering services enable us tailor any of our products to meet clients’ requirements.

Filtration Systems

Cooling/Heating Systems

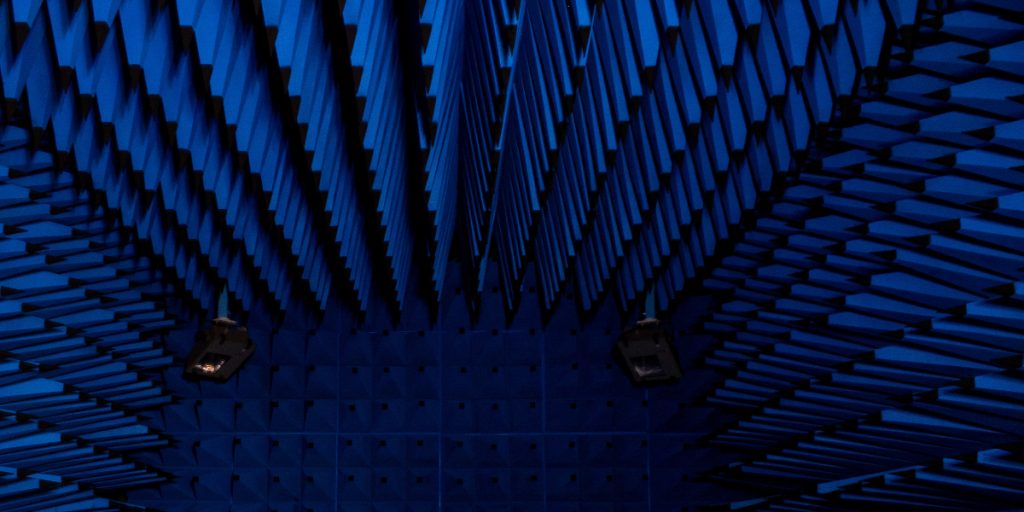

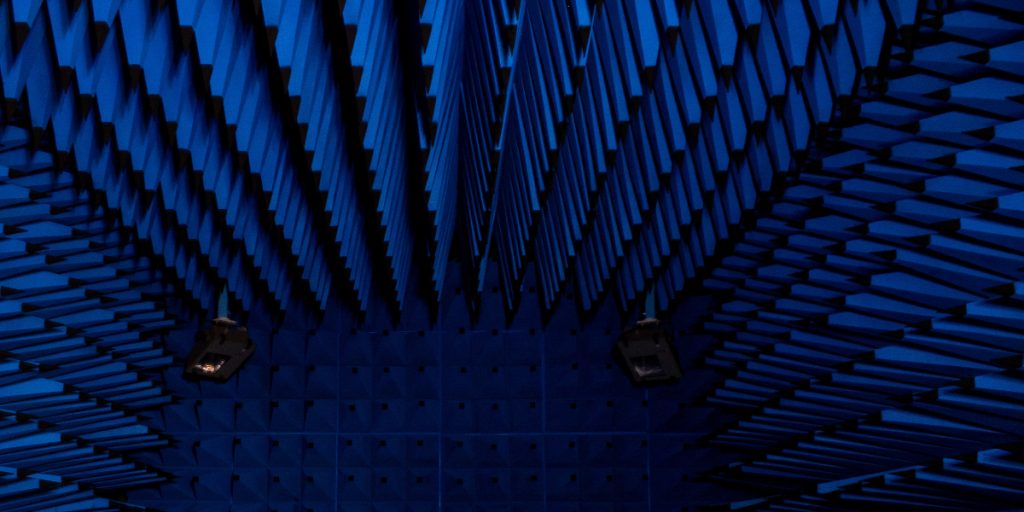

Silencers

Diverter Damper

Exhaust Stacks

Filtration Systems

Cooling/Heating Systems

Silencers

Diverter Damper

Exhaust Stacks

Supporting our clients from research and development, design and drafting to implementation and practical completion.

Our after-sales team provides full support, including retrofits and the supply of spare parts.

Our proven design methodology focuses on creating a functional and state-of-the-art product.

Ensuring client satisfaction through robust, established processes and quality standards, meeting timelines and budgets.

Regardless of size or complexity, we design, manufacture and install your equipment to meet budget and logistics requirements.

With our specialised knowledge and experience, we can deliver and assemble equipment as a single piece, to the requested site.

We provide thorough equipment installation services through trusted local partners to keep costs down, encompassing construction schedule review, site personnel organisation, progress monitoring, supervision, quality checks, and final touch-ups.

Our relationship with our clients does not stop once the supplied equipment is up and running. We guarantees a constant flow of spare parts as required, including technical support from our experts.

Cutting-edge engineering solutions

Engineering for a Sustainable Tomorrow

We specialise in comprehensive acoustic analysis for projects, custom-designing exhaust silencers to meet noise targets efficiently.

We specialise in comprehensive acoustic analysis for projects, custom-designing exhaust silencers to meet noise targets efficiently. These silencers ensure minimal pressure losses while achieving near and far field noise level requirements for gas turbines exhausts, inlet filters and other high flow. We also provide industrial sound barriers as a cost-effective solution for noise reduction from various sources. Provide silencers for gas turbines in the range of 10MW to 500MW, both horizontal and vertical silencer, circular or rectangular.

Used whenever a secondary isolation of the HRSG ducting is required during maintenance works, and are fitted downstream of the diverter damper in a typical Bypass Exhaust System.

We can provide guillotine dampers, either electric or manual operated, and fully automated with the option of providing a Seal-Air System independent of the diverter damper. Custom-designed guillotine dampers can also be supplied for many industrial processes other than isolation of gas turbine exhausts.

We excel in the design and manufacturing comprehensive packages for gas turbine bypass and HRSG exhaust systems, encompassing stacks, silencers, and weather dampers.

A crucial component in combined cycle power plants, these systems ensure safe exhaust gas release to the atmosphere and enable efficient gas turbine operation with minimal pressure drop. Our exhaust stacks feature access ladders, landing and ring platforms, and comply with gas turbine manufacturer regulations, incorporating continuous emission monitoring ports on top.

We design static and pulse-type filter houses, complete with essential support structures.

Static filter houses utilise disposable cartridge-type filters, featuring two filtration levels – coarse pre-filters for larger particles, followed by fine filters. The size is determined by the required interval between filter changes. We also provide necessary ductwork, expansion joints, and silencers for turbine integration if needed.

We employ evaporative cooling by drawing turbine inlet air through wet media, naturally cooling it as water evaporates as well as for extreme cold climates, we deliver innovative Heating Systems for Filter Houses.

Our engineers provide custom designs suited to specific environmental conditions on a case-by-case basis.

Engineering custom diverter dampers for gas turbines, ensuring optimal sizing for any application, providing a sealing efficiency of 100%.

Our portfolio includes the delivery of the largest diverter damper to date: a 6.5m gas path.

Our designs incorporates cold shells with ceramic fibre insulation for diverters, elbows, and exhaust stacks. This design maintains an exterior temperature below 50°C, even with exhaust gas temperatures exceeding 680°C.

We design and install chilling coils inside inlet filter houses to improve the gas turbine performance on hot days.

We also install heating piping (steam or hot water) inside the inlet filter houses to improve part load performance on gas turbine and provide anti icing capabilities when air temperature is below 4oC.