The PFAS Senate Inquiry 2025 marks a turning point for how Australia manages PFAS contamination. With tighter regulation…

The Environmental Group Limited

Category: Waste Management Solutions

Beyond Activated Carbon: Why PFAS Treatment Needs a New Generation of Solutions

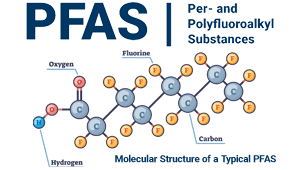

PFAS treatment solutions are shifting beyond activated carbon. As regulations tighten, Australia needs cleaner, scalable technologies that remove PFAS—not just capture it.

Engineering a Greener Tomorrow: Australia’s Opportunity to Lead the PFAS Elimination Era

PFAS elimination Australia is more than a vision—it’s an engineering reality. Discover how we’re turning policy into real environmental progress.

New PFAS compliance standards Australia: EPA-approved PFAS technology helps operators meet them with confidence

PFAS compliance standards Australia are becoming stricter, with new EPA-backed regulations targeting industrial facilities, waste processors, and councils managing leachate and contaminated water.

The way to PFAS extraction

On the search for a viable method for removing PFAS from our water

Bluescope Steel – Sinter Plant Waste Gas Cleaning Plant Bypass

An ambitious project developed by Bluescope that involved the installation of a large regenerable activated carbon filter to clean the gases exiting from the ESP, before they reach the stack for final discharge.

BINGO – Mixed-Waste Recycling Facility | Western Sydney, Australia

The facility has been designed to drastically increase the amount of waste diverted from landfills and manufacturing.

Rino Project – World’s largest Waste Processing Facility

Designed to achieve market-leading landfill diversion and recovery rates of up to 99%, with a processing capacity of 475 tonnes per hour.

Revolutionising Air Quality: Removing Sulphur Dioxide (SO2) from Inlet Gas Streams

Breathing Fresh: Unveiling the Magic Behind Our Air-Cleaning Odyssey

Multi-million-dollar contract in South East Asia

Design, supply and install of a diverter damper exhaust system for a project in Indonesia.